StarSight™ Autonomous System

What is the StarSight™ Autonomous System?

Roborock's StarSight™ Autonomous System leverages industry-first dual-transmitter solid-state LiDAR with 3D Time-of-Flight (ToF) technology to deliver unrivaled navigation.1 Imagine a world where your robot vacuum can see its surroundings in 3D detail, and seamlessly navigate around and under furniture. That's the power of this autonomous system.

Equipped with 21,600 sensor points* for 3D scanning and a sampling frequency 21 times higher than LDS2, it delivers precise localization, comprehensive mapping, and reliable obstacle recognition—all in an impressively compact design. This innovation paves the way for future upgrades and enhanced functionalities, setting a new benchmark for robot vacuum performance.

*The Saros 10R, Saros Z70, and Roborock Qrevo Slim use a QVGA ToF sensor with 21,600 sensor points.

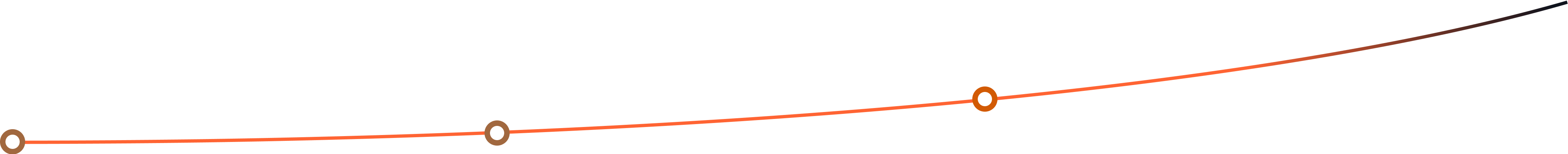

Milestone in Navigation Technologies

Before LiDAR Navigation

Random Collision for Navigation

Gyroscope Navigation

Visual Simultaneous Localization and Mapping (VSLAM)

PreciSense® LiDAR Navigation System

In September 2016, Roborock achieved an early industry breakthrough by mass-producing its LDS-based LiDAR navigation system, improving precision in robot vacuum location and mapping.

StarSight™ Autonomous System

In March 2024, Roborock unveiled the industry's first dual-transmitter solid-state LiDAR, leveraging 3D scanning technology to achieve unparalleled precision and pave the way for future innovations.

The Enhanced StarSight™ Autonomous System 2.0

With cutting-edge VertiBeam™ Lateral Obstacle Avoidance technology, the robot effortlessly maneuvers around irregular furniture and walls, delivering a seamless cleaning experience even in the presence of cables.

Unfolded Cables

Irregular Walls and Furniture

Advantages of the StarSight™ Autonomous System

Enables a Compact Design for Increased Cleaning Coverage

3D Sensing for Precise Mapping Even in Tricky Areas

Suspended Cabinets

Thin-legged Furniture

Under Furniture

Smooth Cleaning with Improved Obstacle Recognition

Small Items*

Unexpected Obstacles

Up to 108 Types of Objects Recognizable

* Based on internal testing carried out by the manufacturer, Saros 10R and Saros Z70 can see and bypass square building blocks down to as small 2cm wide and 2cm tall. Actual accuracy depends on the environment.

What the Experts Say

"Add in the new Time of Flight navigation, which sees the LiDAR dome removed so that the robot can get under more bits of furniture, and the powerful app and this is just about the most flexible robot that I’ve reviewed."

Trusted Reviews

"It will actually be able to SEE that there’s a clump of wires on the floor, it will clean AROUND them, getting as close as it can without getting tangled IN them, and it will even mark them on its MAP of the room so that YOU CAN see the bits YOU need to pick up. And it DOES all this, while ALSO being one of the slimmest robots on the market so it fits under basically anything."

Mrwhosetheboss

"It's even slimmer than some vacuum roller heads, an impressive feat that once felt impossible for robovacs."

TechRadar

Experience the StarSight™ Autonomous System 2.0 with

Saros Z70 with Multifunctional Dock 4.0

Learn More

Saros 10R with Multifunctional Dock 4.0

Learn More

Experience StarSight™ Autonomous System with

Roborock Qrevo Slim with Multifunctional Dock 3.0

Learn More

*Images are for illustration purposes only and may not exactly represent the product.

1.Roborock was the first in the robot vacuum industry to implement 3D ToF functionality using a dual-transmitter approach, as the technology officially launched earlier in 2024.

2.Based on internal testing carried out by the manufacturer using the LDS sampling frequency calculation method.